Compare LVL – All LVL’s are not equal

There are many different brands and grades of LVL (laminated veneer lumber) on the market in Australia. Here we will compare LVL grades and demonstrate that not all LVL’s are equal. For the purpose of this topic, specific branding and products have not been mentioned. We will focus on only strength grades commonly found in Australian hardware stores.

More often or not we hear this comment on site from builders/installers; “it was the closest size i could find to the one i needed”. This often arises when we site measure jobs. Occasionally a beam installed is not what’s been specified by the project engineer. Just like framing pine has different strength grades, so does LVL. It is critical to the performance of the structure being built and the beam/lintel that’s being installed that the correct strength grade of LVL beam is being used; ‘All LVL’s are not equal’.

Knowing LVL Numbers & Grades.

LVL strength grading is usually always in the product name; ‘LVL13 or E13′ would commonly be heard. Both of these names directly relate back to the Modulus of Elasticity. The Modulus of Elasticity or ‘MOE’ is a measure of stiffness of an elastic material. It is the strength grade that tells us how much the material will bend/deflect under specific loading applications. In basic, the higher the number in the product name, the stiffer it is and will deflect less under load. LVL grades commonly seen in Australia range from E10 found in framing studs through to E19 found in LVL structural beams.

What makes one LVL stronger than another?

Visually the majority of LVL’s on the market all look the same. But what makes one LVL stronger than another; is the timber species used and the thickness of laminate veneers. Many producers will use a mixture of soft and hardwood veneers to gain a better MOE value. This also directly effects the sale price of the different products.

Lets Compare LVL Grades.

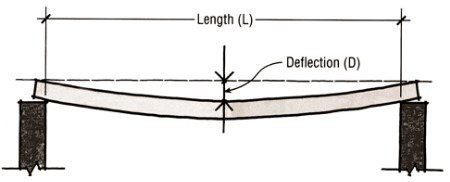

Below is a simple comparison table using some of the strength grades on the market. The table compares each LVL strength grade as a lintel typically found over a 2400 wide sliding door/window. As shown, the higher the LVL grade, the better it performs and minimises the deflection in that lintel. What is deflection you ask? Deflection is the measurement past Horizontal zero. (see Diagram 1)

Deflection is a critical value to consider when designing any beam or lintel. There will always be deflection in any structural member but there are things to consider which can limit this value.

| GRADE | ELASTICITY (mpa) | STRENGTH GROUP | JOINT GROUP | DEFLECTION | STRESS RATIO |

| LVL13 | 13200 | SD5 | JD4 | 8.1mm | 81.2% |

| LVL13.2 | 13200 | SD6 | JD3 | 8.1mm | 81.2% |

| LVL14 | 14000 | SD6 | JD4 | 7.7mm | 76.5% |

| LVL15 | 15300 | SD6 | JD3 | 7.5mm | 74.9% |

| LVL19 | 19500 | SD3 | JD2 | 5.5mm | 55.2% |

Summary-

As the heading states; Not all LVL’s are equal and will not perform the same. So when substituting LVL members, consider its strength grading and not just its physical sectional size. If you are unsure, seek further clarification on a substitution LVL for your next job, talk to your project engineers or CONTACT US

Links:

Learn More about ‘Timber Joint Groups’

Learn more about ‘Timber Strength Groups’